Account

-

Safe payment options

We only work with the most secure payment systems.

-

Product return within 30 days

We do our very best to keep our customers happy.

No products in the cart.

You dont have any products in your cart yet, add a few products to experience this experience.

Add $500.00 to cart and get free shipping!

To see and take advantage of all discounted products.

Click HereCategory: Knowledge Center

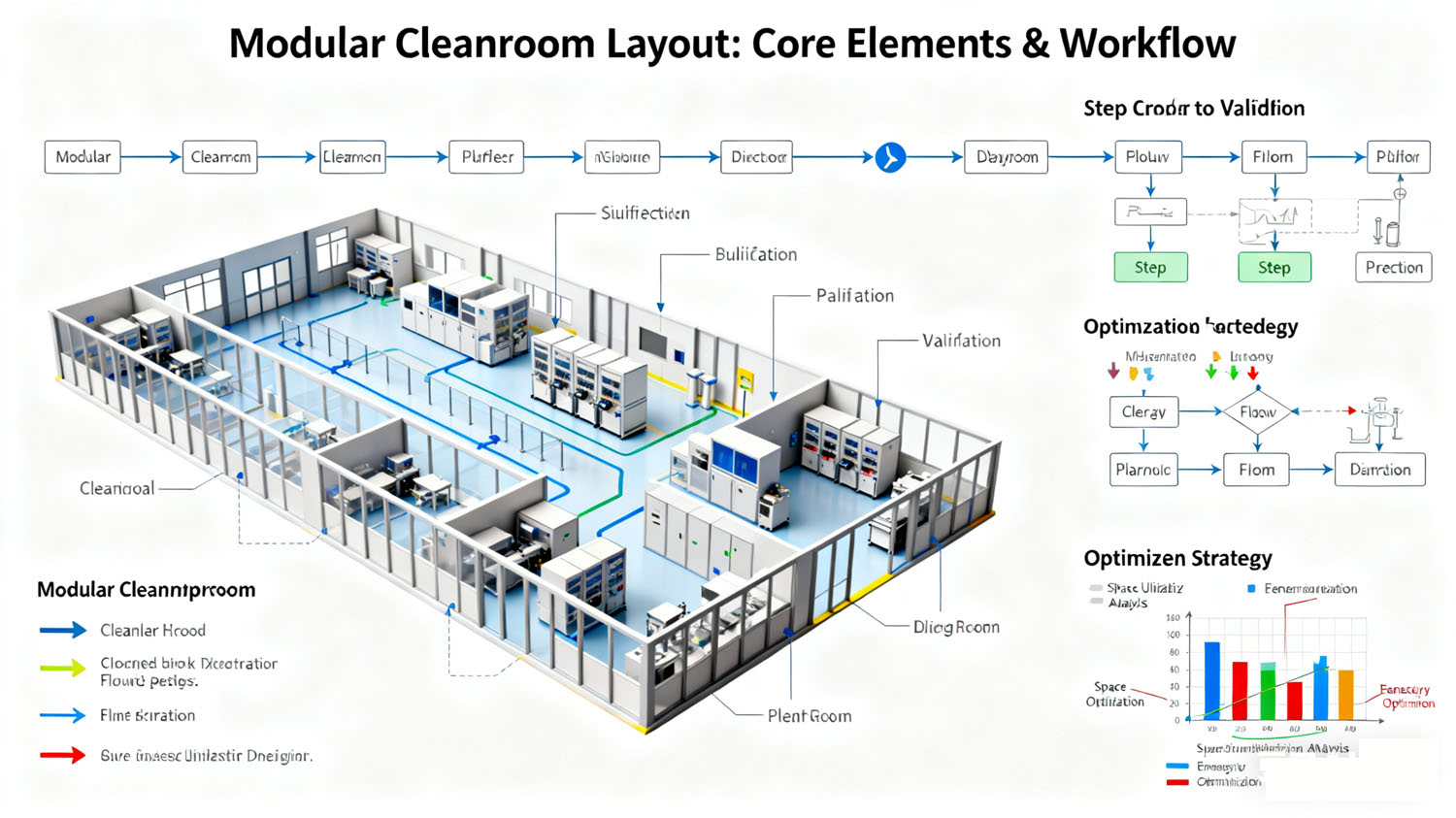

Modular Cleanroom Layout Design: Key Principles, Steps, and Optimization Strategies

Table of Contents Toggle Introduction Understanding Modular Cleanroom Basics Fundamental Principles of Cleanroom Layout Design 3.1 Unidirectional Flow Principle 3.2 Cleanliness Zoning/Grading 3.3 Pressure Differential 3.4 Maintainability & Cleanability 3.5 Scalability & Flexibility 3.6 Safety & Emergency Key Steps in Modular Cleanroom Layout Design 4.1 Phase 1: Requirement Analysis & Goal Setting 4.2 Phase 2:

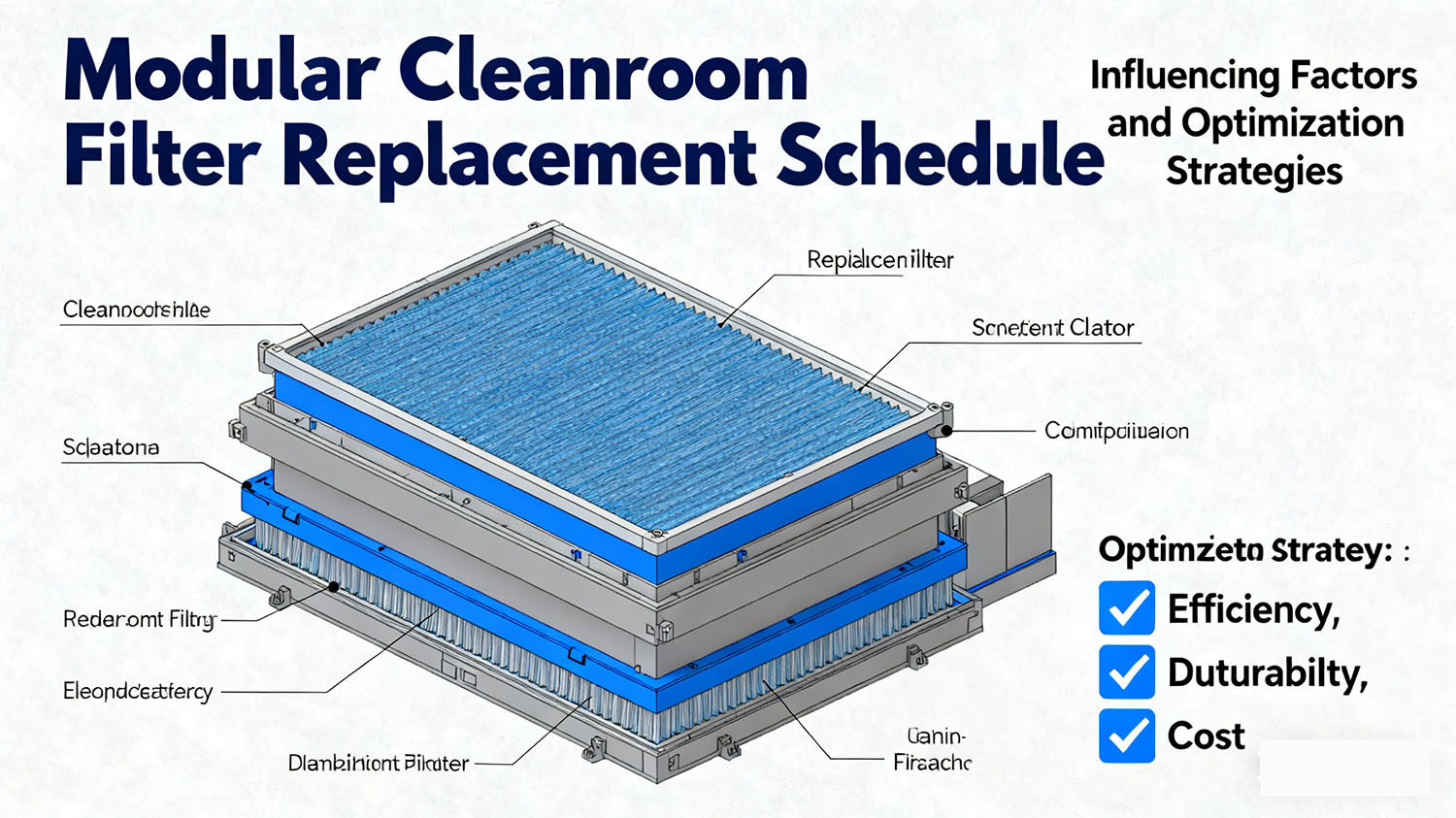

Modular Cleanroom Filter Replacement schedule – Influencing Factors and Optimization Strategies

Cleanroom filters serve as the critical defense mechanism in modular cleanrooms, maintaining stringent cleanliness levels essential for protecting sensitive products and personnel from contamination. The modular cleanroom filter replacement schedule represents a fundamental aspect of operational excellence, directly impacting both compliance and cost-efficiency.Establishing a scientifically-backed modular cleanroom filter replacement schedule is particularly crucial for modular

Modular Cleanroom Maintenance Checklist-Free Printable Templates & ISO Compliance

Modular cleanrooms are prefabricated controlled environments essential for industries requiring contamination control, including pharmaceuticals, biotechnology, medical devices, and electronics manufacturing. Proper maintenance is critical for maintaining ISO classifications and regulatory compliance.This comprehensive guide provides a detailed Modular Cleanroom Maintenance Checklist system that covers all critical aspects of cleanroom upkeep. Implementing a structured Modular Cleanroom Maintenance

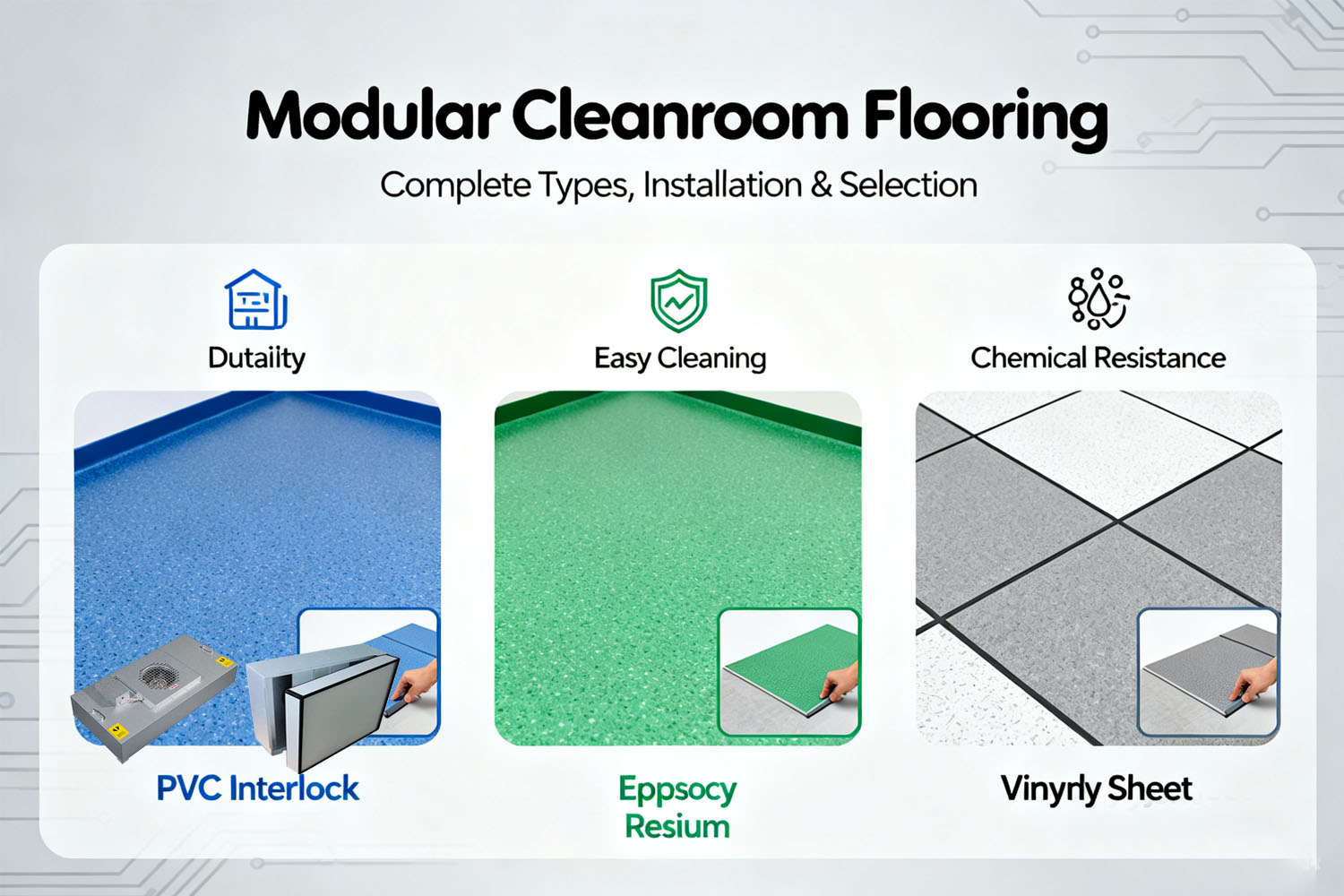

Modular Cleanroom Flooring — Complete Types, Installation & Selection Guide 2025

Selecting the right Modular Cleanroom Flooring is crucial for maintaining contamination control, electrostatic discharge (ESD) protection, and operational efficiency in critical environments. This comprehensive guide from Deiiang™ experts provides data-driven insights to help you make informed decisions about flooring materials, installation methods, and maintenance protocols for your modular cleanroom applications. Executive Summary: Quick Selection Guide

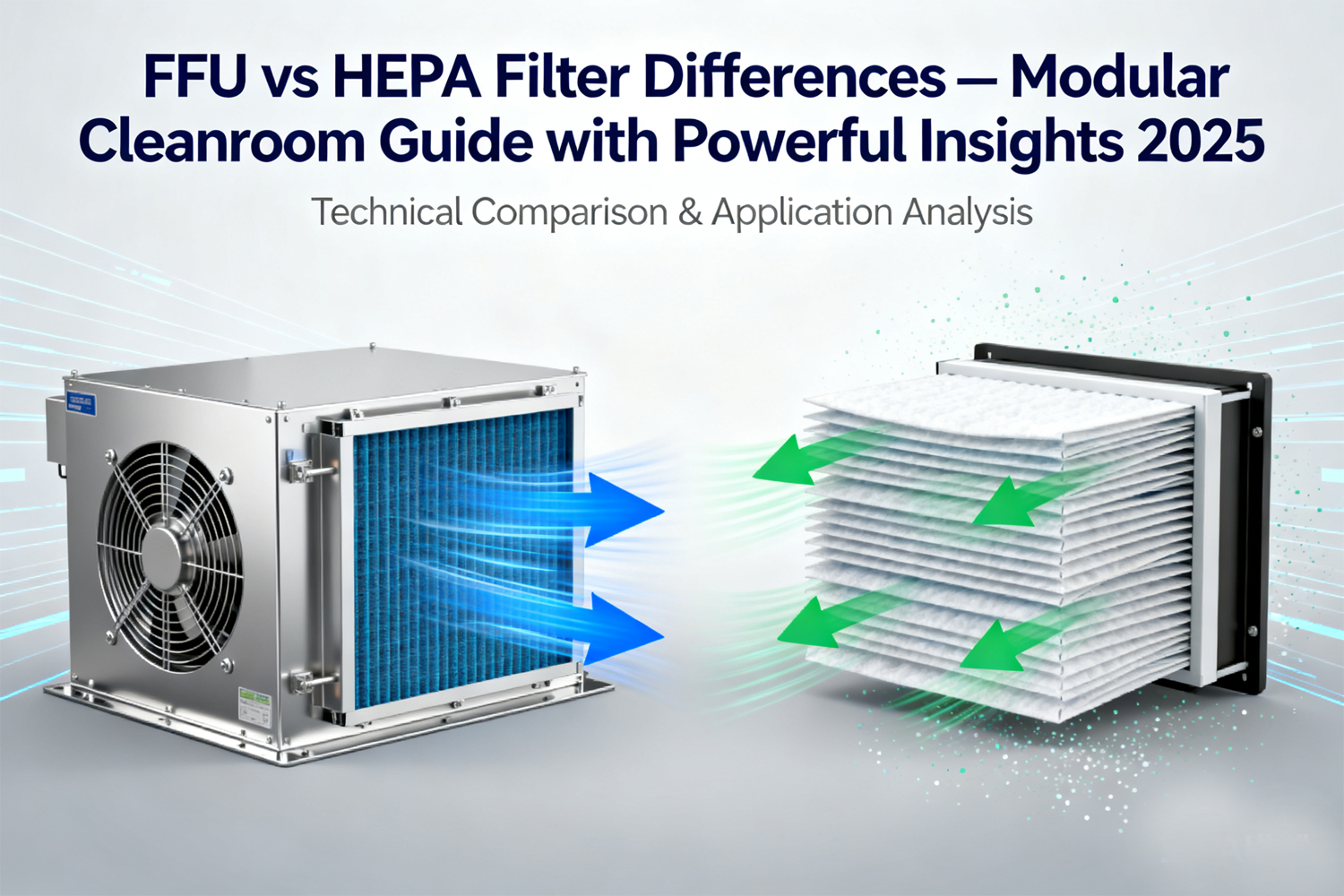

FFU vs HEPA Filter Differences — Modular Cleanroom Guide with Powerful Insights 2025

Making the Right Choice for Your Modular Cleanroom When designing modular cleanrooms, understanding the critical FFU vs HEPA filter differences becomes essential for optimal performance and cost-efficiency. This comprehensive guide from Deiiang™ experts provides data-driven insights to help you make informed decisions between Fan Filter Units (FFUs) and centralized HEPA filtration systems. Quick Decision Guide

Modular Cleanroom HEPA Filter Replacement Cost: Save 20% with Our Complete Price Guide

Table of Contents Toggle Introduction / TL;DR Quick Cost Overview Standard HEPA Filters FFU HEPA Filters Labor & Installation Annual Cost Range Cost Breakdown A. Filter Purchase Cost (Unit Cost) B. Labor Costs C. Verification & Testing Costs D. Supply Chain & Logistics Fees E. Disposal & Handling Costs F. Indirect Costs Replacement Frequency &

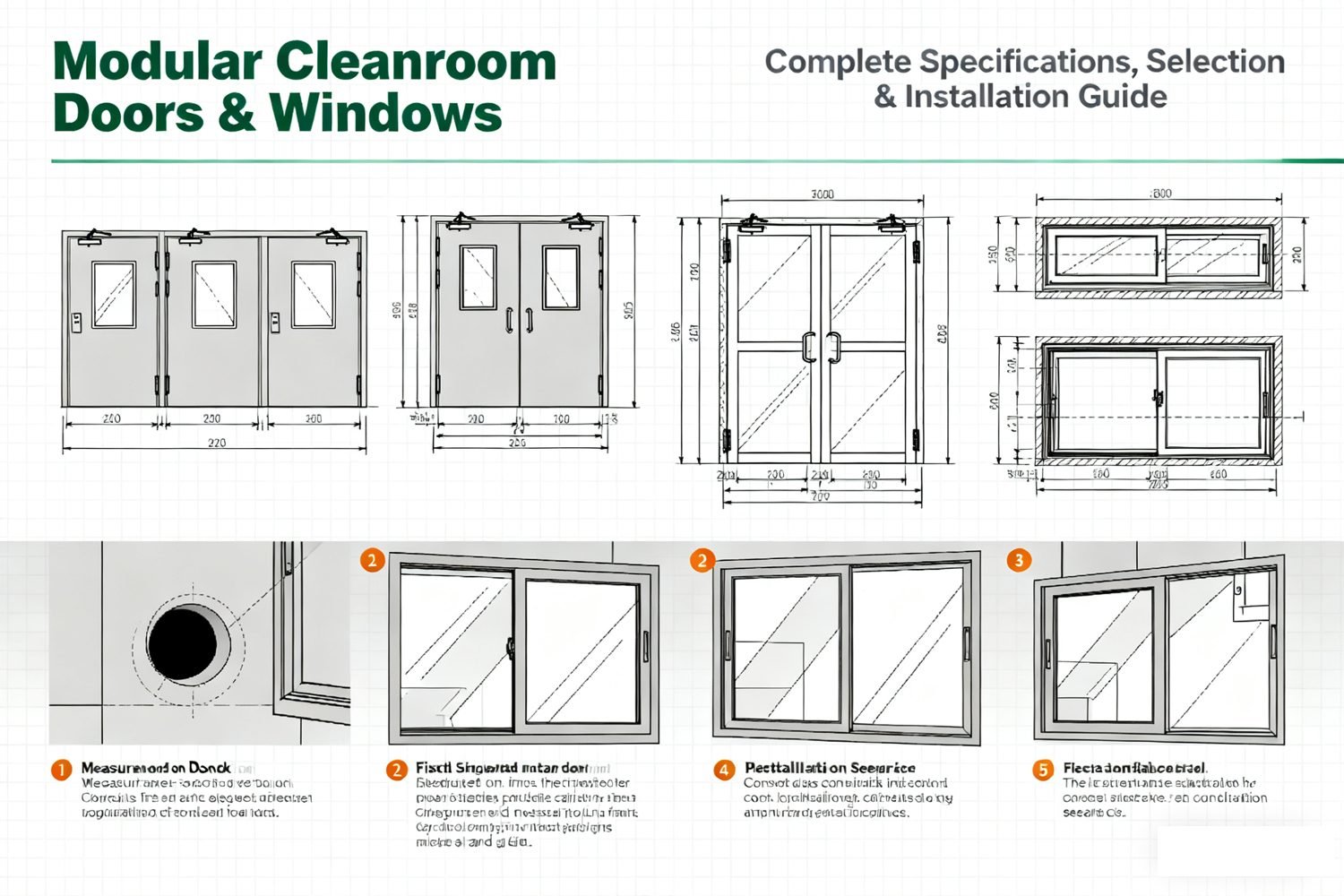

Modular Cleanroom Doors & Windows — Essential 7‑Point Specifications, Selection & Quick Installation Guide

Proper selection of modular cleanroom doors and modular cleanroom windows is critical for maintaining controlled environments. These components directly impact air tightness (≤0.5 L/s·m² leakage), personnel flow (15-20 seconds cycle time), cleaning validation, and overall facility safety. This guide provides comprehensive technical specifications, including detailed performance tables, CAD integration details, and maintenance protocols for optimal

Modular Cleanroom Panels Specifications — Materials, Thickness, Fire Rating & Installation Guide

Modular cleanroom panels specifications determine cleanroom performance, fire safety, and long-term maintenance needs. This guide lists material choices, thickness ranges, thermal and fire ratings, sealing methods and installation notes — plus downloadable CAD and an RFP-ready spec template from Deiiang™. Introduction Proper modular cleanroom panels specifications are critical for facilities in pharmaceutical manufacturing, electronics assembly,

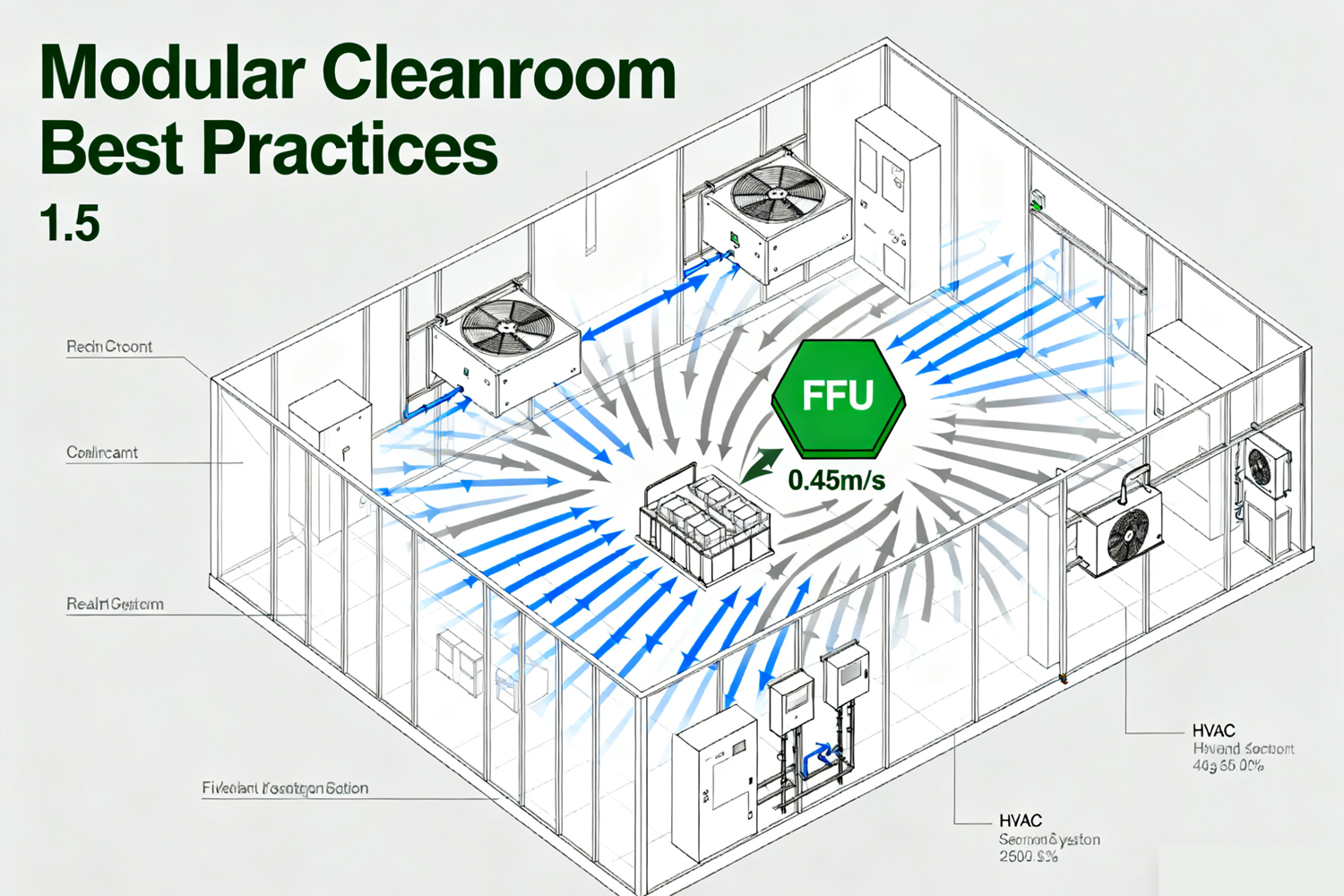

Modular Cleanroom Design — Layouts, FFU & HVAC Best Practices

Introduction to Modular Cleanroom Design Modular cleanrooms provide flexible, cost-effective solutions for industries requiring controlled environments. Whether for pharmaceutical manufacturing [citation:2], electronics assembly, or biotechnology R&D, proper design ensures compliance with ISO 14644 standards [citation:6] and GMP regulations. This comprehensive guide provides layout examples, FFU placement strategies, HVAC Modular Cleanroom Design principles, and technical specifications

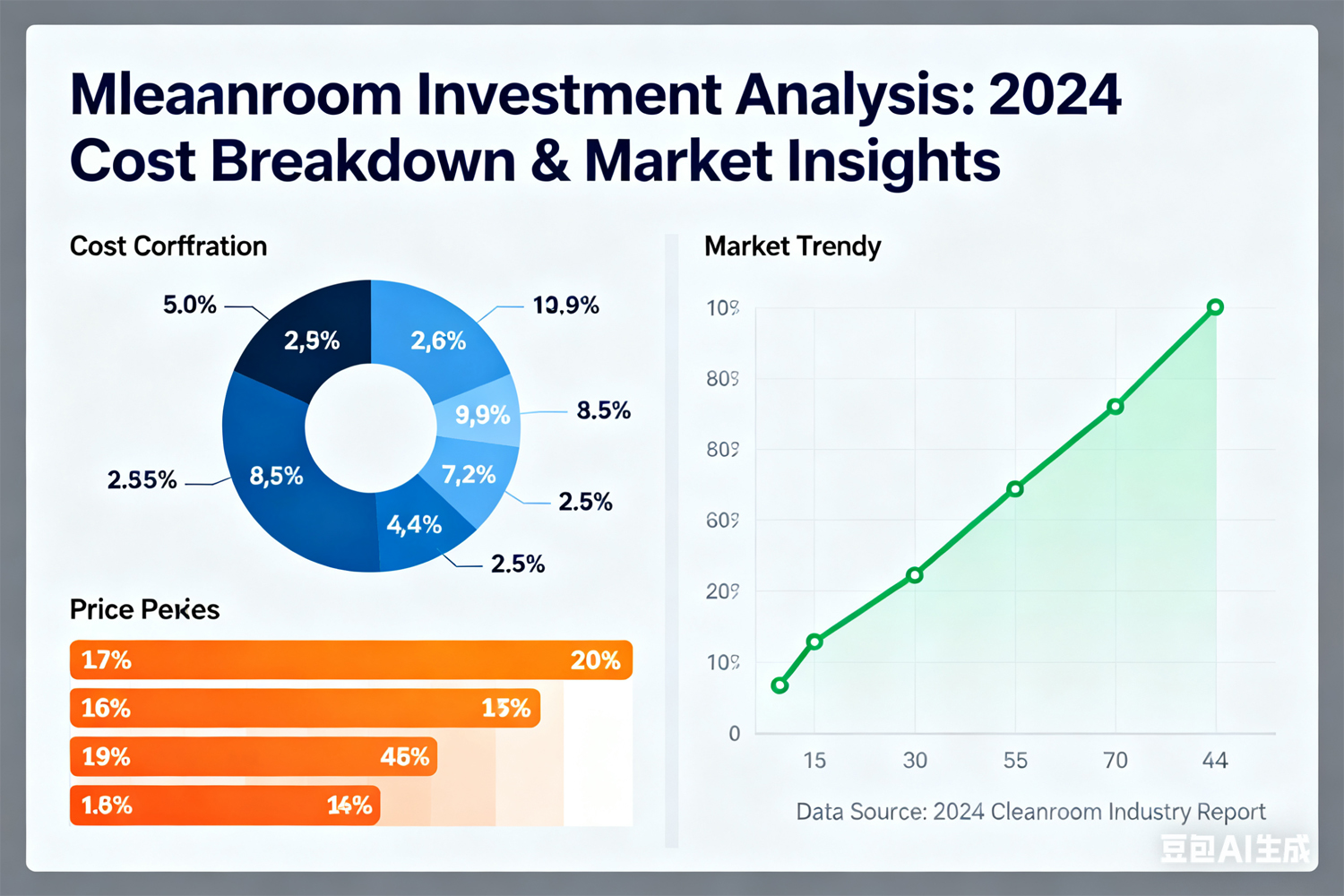

Modular Cleanroom Cost & Price Per Square Foot Guide 2024

Understanding modular cleanroom cost is crucial for budget planning. Typical prices range from $150-450 per square foot, with complete breakdowns available for structure, HVAC, installation, and certification. This guide provides detailed cost analysis, supplier comparisons, and interactive calculators to help you accurately estimate your modular cleanroom investment. Table of Contents Toggle Modular Cleanroom Cost Breakdown